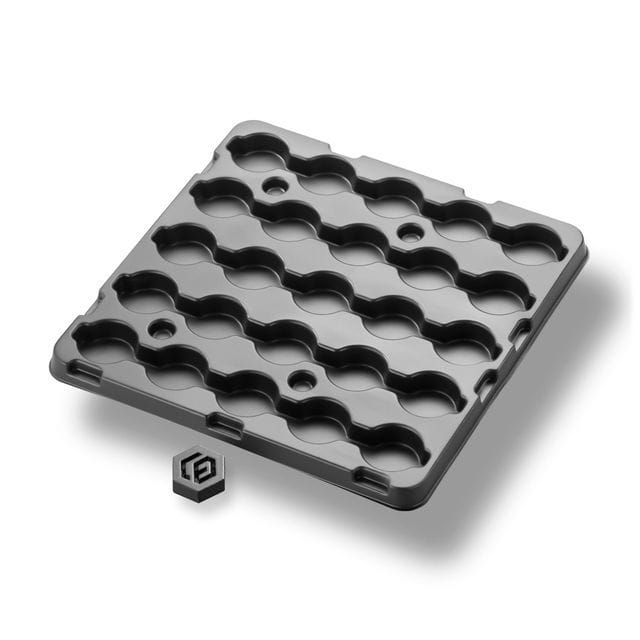

ESD Workpiece Carriers Made of Plastic for Electronics

ESD Workpiece carriers for protection against electrostatic discharge.

ESD Workpiece Carriers Prevent Electrical Charging and Discharging

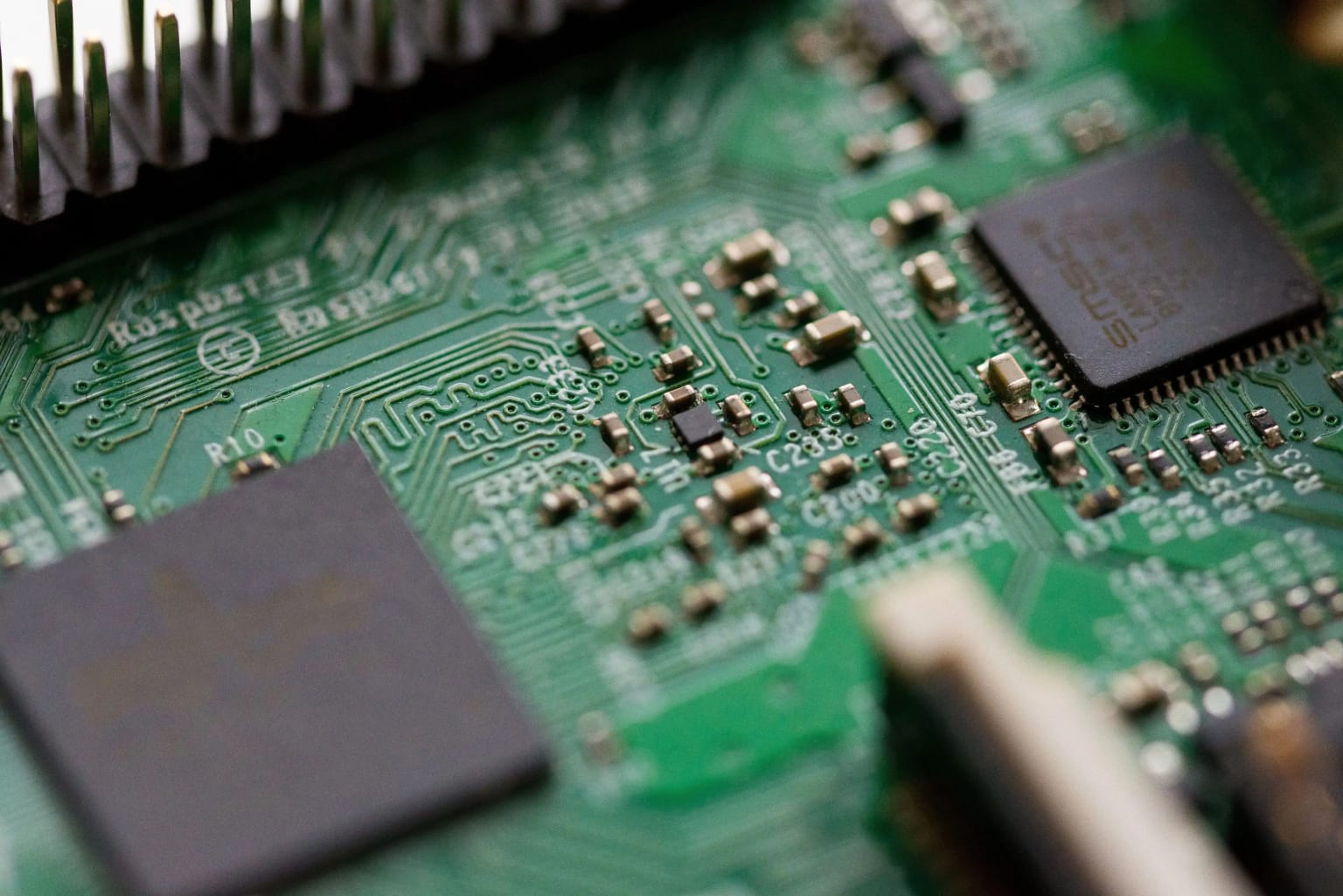

ESD workpiece carriers are used in the electronics industry to protect sensitive electronic components from electrostatic discharges. ESD protective packaging has conductive or dissipative surfaces that discharge static charges to prevent damage to the components. ESD trays are designed for safe transport and storage, as they are stackable, abrasion-resistant, impact-resistant, and resistant to chemicals and water. Workpiece carriers with ESD protection securely position and transport individual components to ensure a controlled environment and protect the quality of electronic components. Common applications include PCBs and circuit boards.

Features of ESD Workpiece Carriers

ESD Workpiece Carriers are Stackable

Handle recesses in ESD workpiece carriers make it easier to ergonomically load the trays into KLTs or outer cartons. This allows ESD trays to be easily gripped, held, carried, taken out of the box, or placed back into the box.

ESD Workpiece Carriers are Robust

ESD workpiece carriers made from plastic-based ESD material impress with their stackable design, reusability, abrasion resistance, impact toughness, and resistance to chemicals and water.

ESD Workpiece Carriers are Tailored

Plastic ESD workpiece carriers are customized to the specific requirements and dimensions of the components to be protected. This ensures an optimal fit and security.

Industries that Use ESD Workpiece Carriers Made of Plastic

Electronics

- Reusable trays

- ESD blister trays for microchips

- Trays for semiconductors

- Tray for PCBs

- ESD trays for assemblies

- Tray for solar cells

- Tray for electronic parts

- Circuit board packaging for electronics

Advantages of ESD Workpiece Carriers Made of Plastic

Weight Optimization

ESD workpiece carriers are often designed to be lightweight without compromising on robustness. This enables easy handling and contributes to reducing the overall weight.

ESD-Compatible Plastics

ESD plastics such as ASA, HD-PE, PS, PP, PMMA, and PC are used to reliably prevent the generation of electrostatic charge and dissipate existing charges.

Abrasion Resistance

The durability of workpiece carriers in ESD design ensures excellent resistance to wear and tear during transport and handling.

Process Optimization

ESD workpiece carriers made of plastic come with practical handle recesses that facilitate efficient packing, stacking, transporting, storing, and shipping.

Impact Toughness

ESD workpiece carriers are resistant to impacts and mechanical stresses, ensuring that the electronic components remain protected.

Chemical Resistance

ESD workpiece carriers with ESD protection are resistant to various chemicals, making them useful where contact with specific substances is unavoidable.

Applications of ESD Workpiece Carriers for Electronics

ESD Protective Packaging as a Protective Measure in the Automotive Industry

ESD workpiece carriers are used in the automotive industry, especially when processing electronic components like sensors, control units, and other sensitive parts. Protection against electrostatic discharge is critical here to ensure the reliability and longevity of sensitive components.

ESD Workpiece Carriers Protect PCBs & Circuit Boards

ESD workpiece carriers provide a safe and protected environment for circuit boards and PCBs during assembly, storage, or transport. They are often used in conjunction with antistatic packaging materials and workstation surfaces to ensure an ESD-safe environment.