Design for Manufacturing (DfM): Guide to Manufacturing-Oriented Design

With the new Design for Manufacturing analysis from formary, it is now possible to check CAD data for thermoformability in a matter of seconds, allowing potential sources of error to be identified early on before they become costly. Read on to find out what features the DfM software offers and what the Design for Manufacturing principle entails.

Sarah Guaglianone

13. Januar 2026

Contents

Design for Manufacturing – The most important facts

- Design for Manufacturing (DfM) means designing products so that they can be manufactured easily, economically, and with few errors.

- With a DfM analysis, you can identify manufacturing problems as early as the design phase.

- The new DfM tool by formary enables an automated analysis of your 3D models quickly, accurately, and free of charge in your browser.

→ Go directly to DfM Analysis: formary.de/en/3d-services/dfm-analyse

What is Design for Manufacturing?

DfM Meaning: Design for Manufacturing, Design for Manufacturability (DfM), or “manufacturing-oriented design,” refers to a design approach in which components are created in such a way that they can be produced easily, efficiently, and cost-effectively while maintaining high quality.

In short: DfM ensures that from the design stage it is clear how the product can be manufactured later on, helping customers save both time and money.

How does Design for Manufacturing work?

Design for Manufacturing works by checking already during the design phase whether a component is manufacturable. There are clear manufacturing rules and criteria such as wall thicknesses, radii, or moldability:

- Analysis of geometry for manufacturability

- Identification of critical areas (e.g., overly thin wall sections)

- Adjusting the design for optimization

- Validation and release for the manufacturing process

The 5 Design for Manufacturing Principles

Design for Manufacturing is based on five key principles that help solve manufacturing issues early in the design phase.

| Design for Manufacturing Principle | Application in the Development Process | Problems Solved by DfM |

|---|---|---|

| 1️⃣ Error prevention in design | Identify and eliminate potential error sources early | Fewer complaints, higher quality |

| 2️⃣ Manufacturing-oriented design | Consider appropriate processes and materials | Improved manufacturability, reduced production costs |

| 3️⃣ Reducing the number of parts | Design with as few individual parts as possible | Less assembly effort, fewer error sources |

| 4️⃣ Standardized components | Use standard parts instead of custom-made ones | Shorter lead times, lower costs, easier sourcing |

| 5️⃣ Modularization of design | Divide components into interchangeable modules | Better maintainability, easier variant production |

Advantages of Design for Manufacturing

Thanks to its core principles, DfM analysis offers numerous benefits:

- Early error detection: Critical areas are identified directly in the CAD model

- Cost reduction: Avoidance of expensive rework and complaints

- More efficient processes: Fewer queries and delays during development

- Improved quality: Better feasibility and reproducibility in series production

- Planning reliability: Clear communication with manufacturing and tooling departments

- Adaptable to different manufacturing processes: Whether injection molding, 3D printing, or vacuum forming, DfM supports all common manufacturing methods.

What Does DfM Analysis Mean for the Thermoforming Process in Practice?

When designing a plastic thermoformed parts such as plastic covers or plastic containers, this means, for example:

- Optimizing wall thicknesses to ensure even material distribution

- Designing radii so that they can be thermoformed without issues

- Building components modularly to allow for product variants

- Using standardized mounts or fasteners

- Considering draft angles to enable easy removal from the mold

What Are the Challenges and Disadvantages of DfM?

Although Design for Manufacturing offers many benefits, there are typical challenges in practice:

- Often requires extensive experience: Designers must consider complex manufacturing rules

- Time-consuming manual checks: Without software tools, wall thicknesses, radii, and draft angles must be analyzed manually

- Risk of errors: Human judgment is error-prone and can lead to costly rework

- Communication problems: Without clear visualization, misunderstandings can occur between design and tooling departments

The Solution: DfM Analysis of Plastic Thermoformed Parts in Seconds

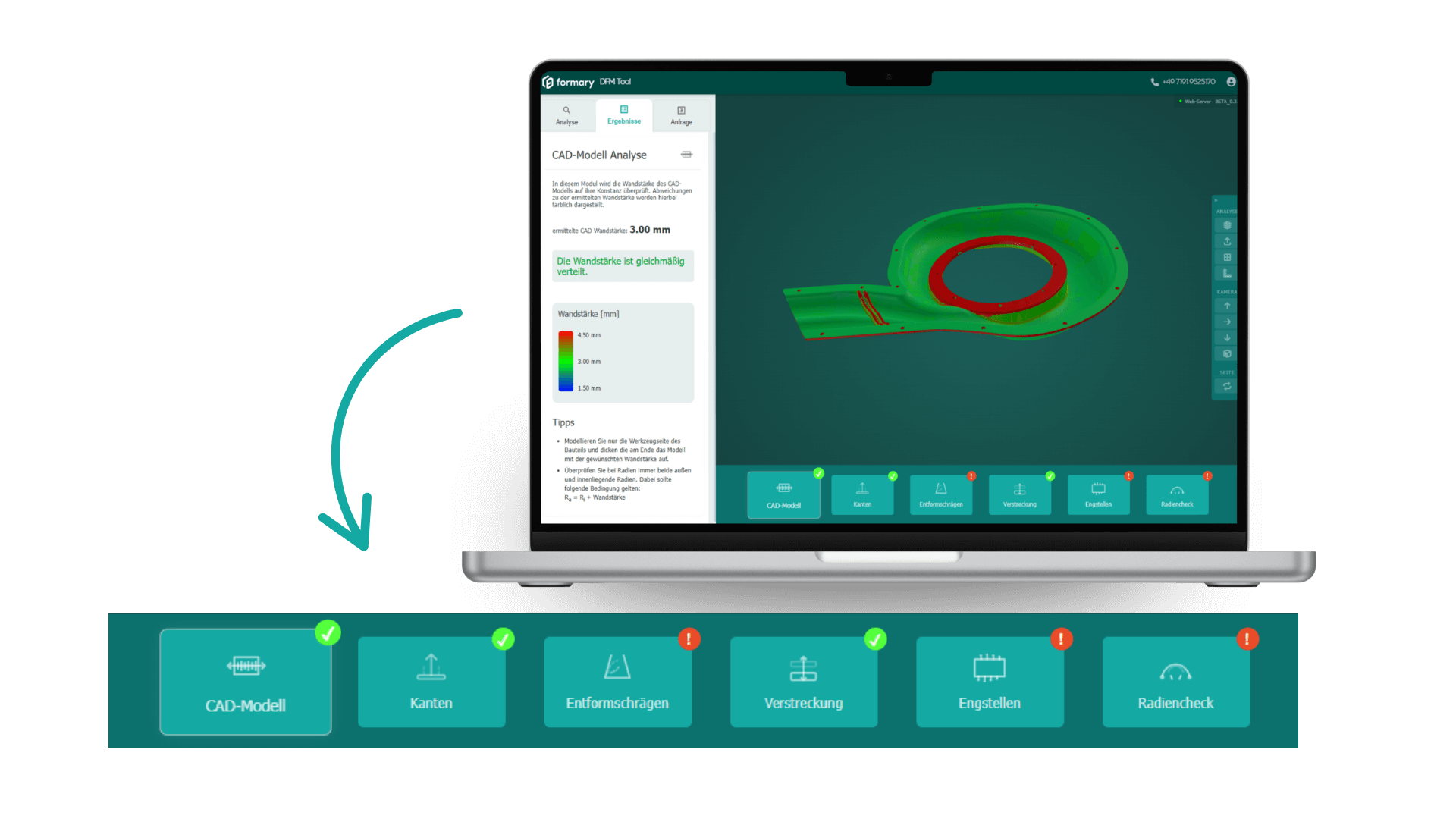

Upload your thermoforming part data, and our DfM software will evaluate whether it can be manufactured as designed, or which geometries need to be modified for technical, functional, or cost-related reasons. These modifications can then be carried out either by you or by us.

How Does the DfM Analysis Work?

- Upload STEP file

- Automatic analysis in about 60 seconds

- Color-coded results for:

- Wall thickness distribution

- Radii

- Edges and draft angles

- Stretching ratio

- Narrow sections and details

Advantages of the DfM Tool

- Automated analysis in seconds

- Color-coded and visually intuitive

- No waiting times or manual queries

- Detect errors early and reduce costs

- Usable directly in the browser

- No expert knowledge required

- Provides a basis for smooth coordination with toolmaking

ℹ️ For more details about the DfM analysis, visit: formary.de/en/3d-services/dfm-analyse

Frequently Asked Questions About the DfM Analysis

What is Design for Manufacturing?

Design for Manufacturing (DfM) means designing products so they can be manufactured efficiently, cost-effectively, and without errors. The goal is to consider all manufacturing aspects right from the design stage.

What does DfM mean?

DfM stands for “Design for Manufacturing” and describes a design approach that optimizes manufacturability and production costs from the very beginning.

How much does the DfM analysis cost?

The use of our tool is free of charge.

Which formats does the tool support?

Currently: .STEP files for 3D CAD models.

Who is the analysis suitable for?

Designers, engineers, and companies aiming to manufacture thermoformed parts efficiently and reliably.

How long does the DfM analysis take?

The analysis usually takes less than a minute, depending on model complexity.

Design for Manufacturing for Plastic Thermoformed Parts – Now Easier Than Ever

Design for Manufacturing ensures that your products are manufacturable right from the start. With our free DfM analysis, you can check your design in about 60 seconds—for fewer errors, lower costs, and smoother workflows.

→ Book your demo now!